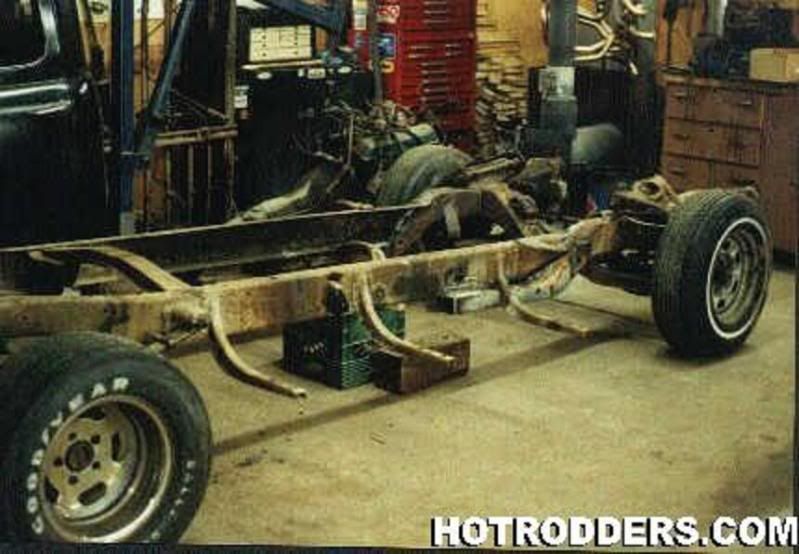

I will be grafting in a 75-79 Nova subframe into my 1953 Chevy 3100 Pick-up.

I noticed that the front tires sit farther back in the wheel well when there is no engine/transmission in these vehicles.

How do you guys go about properly locating the front ends when grafting in a newer subframe such as mine?

Thanks!

I noticed that the front tires sit farther back in the wheel well when there is no engine/transmission in these vehicles.

How do you guys go about properly locating the front ends when grafting in a newer subframe such as mine?

Thanks!