I have 6 vehicles with H.E.I. distributors, lately I've had a run on failed modules, especially the performance models, especially the Mallory brands. The stock modules seem to last longer than the racing models, some have gone bad just sitting in the garage. Any ideas, I'm on the way to buy another one.

harleypc

HEI Modules

1 reading

harleypc

Discussion starter

16 posts

·

Joined 2011

- Add to quote Only show this user

I have 6 vehicles with H.E.I. distributors, lately I've had a run on failed modules, especially the performance models, especially the Mallory brands. The stock modules seem to last longer than the racing models, some have gone bad just sitting in the garage. Any ideas, I'm on the way to buy another one.

1,401 posts

·

Joined 2011

Performance Distrbuters in Tenn. sells a heavy duty module made by D.U.I. Not sure if its American made or not, but I have had good luck with it

20,998 posts

·

Joined 2009

I'm not aware of a good back-to-back-to-back type test of HEI modules- and that would be something that I bet a lot of guys would be interested in, including ME!harleypc said:I have 6 vehicles with H.E.I. distributors, lately I've had a run on failed modules, especially the performance models, especially the Mallory brands. The stock modules seem to last longer than the racing models, some have gone bad just sitting in the garage. Any ideas, I'm on the way to buy another one.

The first thing I'd suspect is heat is killing them. Modules have to have heat sink compound on the back so they can use the distributor body as a heat sink. Otherwise the module can overheat and fail. I often hear dielectric grease being recommended as a heat sink compound. My thoughts on this is that dielectric grease is not good as a heat sink compound- BUT it may be better than nothing. I DO know there are good products available that will work much better than any non heat sink compound, like described http://www.crankshaftcoalition.com/wiki/Hot_rodding_the_HEI_distributor#Module, under Module.

Next would be a good ground path. The screw hole reinforcement sleeve also acts as the ground. The distributor is grounded to the engine block through the clamp and secondarily through the gear, bushings, etc. (but I wouldn't rely on just that). If the clamp, clamp bolt, and/or distributor body has paint or grease on it, that could keep the module from grounding as it should. The engine block also needs to have a good ground path to the battery as well as the firewall.

The HEI needs full battery current to work right. I don't thing not having enough current would cause a module to fail, but too much current sure can. So if the voltage regulator were to be allowing voltage spikes, that could cause a module to fail.

10,098 posts

·

Joined 2005

The other thing is that there are many reboxed stock replacement offshore modules, which all suck, they fail early and they tend to put out a lot of signal noise, I went through 3 modules in a month before I went to a better brand. These were NOT performance modules though and I have never used a mallory one.cobalt327 said:I'm not aware of a good back-to-back-to-back type test of HEI modules- and that would be something that I bet a lot of guys would be interested in, including ME!

The first thing I'd suspect is heat is killing them. Modules have to have heat sink compound on the back so they can use the distributor body as a heat sink. Otherwise the module can overheat and fail. I often hear dielectric grease being recommended as a heat sink compound. My thoughts on this is that dielectric grease is not good as a heat sink compound- BUT it may be better than nothing. I DO know there are good products available that will work much better than any non heat sink compound, like described http://www.crankshaftcoalition.com/wiki/Hot_rodding_the_HEI_distributor#Module, under Module.

Next would be a good ground path. The screw hole reinforcement sleeve also acts as the ground. The distributor is grounded to the engine block through the clamp and secondarily through the gear, bushings, etc. (but I wouldn't rely on just that). If the clamp, clamp bolt, and/or distributor body has paint or grease on it, that could keep the module from grounding as it should. The engine block also needs to have a good ground path to the battery as well as the firewall.

The HEI needs full battery current to work right. I don't thing not having enough current would cause a module to fail, but too much current sure can. So if the voltage regulator were to be allowing voltage spikes, that could cause a module to fail.

DUI modules seem to have a good reputation and I have never had problems with an ACDelco module, there's another brand I just started using as well that seems to be holding up fine but the name escapes me at the moment, its something like BRG but that's not it. Its 3 letters beginning with a B.

3,863 posts

·

Joined 2012

bwd (borg warner)The other thing is that there are many reboxed stock replacement offshore modules, which all suck, they fail early and they tend to put out a lot of signal noise, I went through 3 modules in a month before I went to a better brand. These were NOT performance modules though and I have never used a mallory one.

DUI modules seem to have a good reputation and I have never had problems with an ACDelco module, there's another brand I just started using as well that seems to be holding up fine but the name escapes me at the moment, its something like BRG but that's not it. Its 3 letters beginning with a B.

20,998 posts

·

Joined 2009

My post above should have contained the following link:

X2 on GM modules being reliable. Don't know how they stack up performance-wise, but they DO last.

DV, are you thinking of "BWD" modules?

Sorry if it caused any confusion. :drunk:cobalt327 said:I DO know there are good products available that will work much better than any non heat sink compound, like described HERE, under Module.

X2 on GM modules being reliable. Don't know how they stack up performance-wise, but they DO last.

DV, are you thinking of "BWD" modules?

10,098 posts

·

Joined 2005

yea, BWD, I believe they are american made too, and they were about twice as heavy and appeared more solid than the offshore crap it replaced. Its working very well so far.cobalt327 said:My post above should have contained the following link:

Sorry if it caused any confusion. :drunk:

X2 on GM modules being reliable. Don't know how they stack up performance-wise, but they DO last.

DV, are you thinking of "BWD" modules?

156 posts

·

Joined 2012

I have been reading up on this lately , not claiming to be a expert. I have also read that heat no heat sink compound will kill them, just heat in general. It seems that the GM modules are pretty darn good and I have taken a trip the the local scrap yard and got a handfull of 990's for free. IMO also the modules,GM, are not the problem . You have some thing else killing them. I think we need more info on your set up to help. What coils are you running ? internal or external?

Have also came across the mallory dist and parts being junk, not what they used to be.

HEI likes nice big 12v hot wire with no resistor.

Look up layer shorting in the coil, I think this is a main cause of failed modules.

Have also came across the mallory dist and parts being junk, not what they used to be.

HEI likes nice big 12v hot wire with no resistor.

Look up layer shorting in the coil, I think this is a main cause of failed modules.

20,998 posts

·

Joined 2009

I've been lucky- I have never had an HEI coil fail.

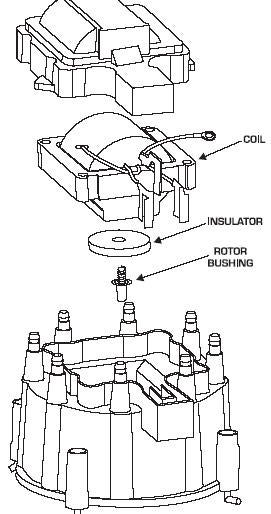

Something else to check: I've had the center electrode burn out ("rotor bushing" in diagram below), deformed the plastic of the cap- made a mess. Also check to be sure the little spring that contacts the bottom of the coil is in place and hasn't been lost or overheated.

![Image]()

Here's another page on HEI coils/modules and a thread I bookmarked that might be interesting.

Something else to check: I've had the center electrode burn out ("rotor bushing" in diagram below), deformed the plastic of the cap- made a mess. Also check to be sure the little spring that contacts the bottom of the coil is in place and hasn't been lost or overheated.

Here's another page on HEI coils/modules and a thread I bookmarked that might be interesting.

harleypc

Discussion starter

16 posts

·

Joined 2011

HEI modules Do mean BWD? A guy at Advance put me on to them today, I will test them.

do you mean BWD Z-SERIES? A guy at Advance put me on to them this afternoon, I will test them out . I also heard that running a ground wire from the vacuum advance mounting screw to the engine block may work also. Thanks.....pcap72 said:The other thing is that there are many reboxed stock replacement offshore modules, which all suck, they fail early and they tend to put out a lot of signal noise, I went through 3 modules in a month before I went to a better brand. These were NOT performance modules though and I have never used a mallory one.

DUI modules seem to have a good reputation and I have never had problems with an ACDelco module, there's another brand I just started using as well that seems to be holding up fine but the name escapes me at the moment, its something like BRG but that's not it. Its 3 letters beginning with a B.

264 posts

·

Joined 2010

Running that ground is a good idea. You could take it all the way to the ground screw under the rotor for the module.harleypc said:do you mean BWD Z-SERIES? A guy at Advance put me on to them this afternoon, I will test them out . I also heard that running a ground wire from the vacuum advance mounting screw to the engine block may work also. Thanks.....pc

I use BWD from advance on customer stock vehicles.

However, check out MSD digital HEI modules. I won't use anything else on my personal and customers performance vehicles. They have a large heat sink area, programmable rev limiter(without removing the cap or pills), an external ground lead that is plenty long, and have very clean electronic signals(radio, dakota digital dash, and etc). I use them in trucks for towing, drag cars(street cars), and all the way up to circle track cars without alternators(they r easier on battery life and have more oomph). I have only had one fail, and im fairly certain it was my fault. I ran the ground to the carb stud instead of the block or at the engine ground strap, DOH! :spank: .

They are a little expensive, but after you buy three high end replacement modules you could have bought the MSD Digital HEI module, and it comes with a rev limiter and tachometer check!

I am also curious to see what you find with your back to back failures.

15 posts

·

Joined 2013

Guys - This is an interesting thread on modules and with the problem I'm having with my 63 Avanti's 350 Chevy chugging and dying, I'm less convinced it's fuel delivery and more persuaded it's electric.

Going to test voltage on the BATT clip first. Impedance seems correct for the coil and if the voltage is a steady 12 or 13v on the BATT terminal, I'm suspecting the module.

Going to test voltage on the BATT clip first. Impedance seems correct for the coil and if the voltage is a steady 12 or 13v on the BATT terminal, I'm suspecting the module.

20,998 posts

·

Joined 2009

Might want to keep everything on the thread you started, but in any event, the module is easy enough to swap out. Most guys who run HEI ignitions have a few on hand "just in case". If you don't, ask around- someone will have one to try out.

• HEI distributor info

Good luck.

• HEI distributor info

Good luck.

6,969 posts

·

Joined 2003

I was advised by Mark Hamilton at MadElectrical to purchase this Delco module.

Attachments

-

174.2 KB Views: 829

20,998 posts

·

Joined 2009

That's a good module, sometimes called a "990" series module. Used in the ZZ4. GM p/n GM #10482820.

Other 'good' numbers:

Other 'good' numbers:

- Standard Ignition/Bluestreak p/n LX-301

- Borg Warner CBE4

- Echlin TP-45

- Standard LX-301

92 posts

·

Joined 2013

I was reading this thread and nodding my head with the fact that I too seem to be another victim of a poor quality off shore module.

Initially I was experiencing an engine miss under high load which prompted me to replace the plugs, wires, dist cap and rotor, also the external coil { its a 95 truck with the 350 TBI }. None of those items made any difference so I took it to my mechanic to check things out and from his experience he felt the original distributor was most likely at fault and replace it with a "new" one from a parts supplier. Yes, that did solve the miss under load so I can only assume ether the old module or the distributor possibly becoming magnetized could have been the cause. So I thought all should be good now but no, a week later the engine would start and quit a few times before it would stay running, also quit randomly when coming to a stop and not on the throttle or buck and jerk the driveline violently out of the blue when at lower rpm but high load. Long story short, the module kicked out a code so the engine check light was on and it was tested at a shop and they said the body of the module was not grounding because of an internal failure. I replaced it myself with a GM Delco unit and that part of the dist has been good since. I did note that the prongs were physically smaller in diameter on the aftermarket module compared to the GM one which in my mind told me it was manufactured as cheaply as possible. Now I am having the gear on this same unit wearing at a high rate after replacing the cam shaft and I called the rep for the company that supplies this brand of new or reman parts and he said right off ... these distributors even though they are brand new, are junk !. My jaw fell open for the simple reason, how often do you hear the rep for a supplier of parts just out and out tell a customer that sadly they are handling a totally inferior product. I was going to replace the gear with a genuine GM unit but then come to find the shaft size is unique to the offshore unit so .... I ordered a brand new GM Delco distributor and the parts supplier will take this one back !. What a gong show and the insane amount of shop $$$ to figure out its due to poor quality parts.

So StudebakerTom, beware the offshore pitfalls of "will fit parts" and if you need to replace a cap/coil or module, choose one that these gentlemen are suggesting rather then be tempted by a lower price.

Initially I was experiencing an engine miss under high load which prompted me to replace the plugs, wires, dist cap and rotor, also the external coil { its a 95 truck with the 350 TBI }. None of those items made any difference so I took it to my mechanic to check things out and from his experience he felt the original distributor was most likely at fault and replace it with a "new" one from a parts supplier. Yes, that did solve the miss under load so I can only assume ether the old module or the distributor possibly becoming magnetized could have been the cause. So I thought all should be good now but no, a week later the engine would start and quit a few times before it would stay running, also quit randomly when coming to a stop and not on the throttle or buck and jerk the driveline violently out of the blue when at lower rpm but high load. Long story short, the module kicked out a code so the engine check light was on and it was tested at a shop and they said the body of the module was not grounding because of an internal failure. I replaced it myself with a GM Delco unit and that part of the dist has been good since. I did note that the prongs were physically smaller in diameter on the aftermarket module compared to the GM one which in my mind told me it was manufactured as cheaply as possible. Now I am having the gear on this same unit wearing at a high rate after replacing the cam shaft and I called the rep for the company that supplies this brand of new or reman parts and he said right off ... these distributors even though they are brand new, are junk !. My jaw fell open for the simple reason, how often do you hear the rep for a supplier of parts just out and out tell a customer that sadly they are handling a totally inferior product. I was going to replace the gear with a genuine GM unit but then come to find the shaft size is unique to the offshore unit so .... I ordered a brand new GM Delco distributor and the parts supplier will take this one back !. What a gong show and the insane amount of shop $$$ to figure out its due to poor quality parts.

So StudebakerTom, beware the offshore pitfalls of "will fit parts" and if you need to replace a cap/coil or module, choose one that these gentlemen are suggesting rather then be tempted by a lower price.

1,847 posts

·

Joined 2009

There are so many options,,, this is one that makes sense. Over seas module? dont know, dont care. Mine has 15 ooo miles on it and never missed a beat. I know of few more of these, not one problem, try and beat the value.

White Performance Detail Description

White Performance Detail Description

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 2.2M

- members

- 183K

- Since

- 2001

A forum community dedicated to hot rod owners and enthusiasts. Come join the discussion about restoration, builds, performance, modifications, classifieds, troubleshooting, maintenance, and more!

Explore Our Forums

Top Contributors this Month

View All

Scott Danforth

145 Replies

BogiesAnnex1

78 Replies

1971BB427

53 Replies