Just a little tip on cutting a nice hole in sheet metal. I needed to cut open a hole in the door shell of my truck so I could relocate the window channel and it's welded in from the factory. The doors on these trucks had no hole as the whole inside of the door was painted and it only had a very small trim panel at the top. My passenger door had a bunch of holes drilled in it from some speaker installation years ago by a previous owner.

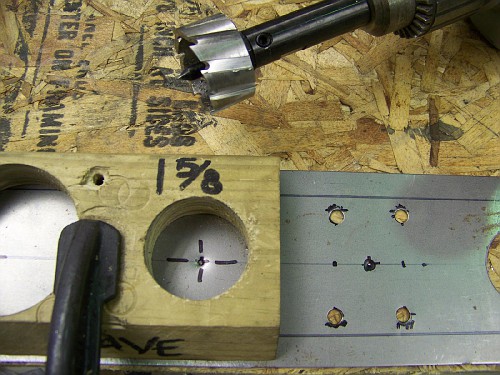

So I thought that was the perfect place to place my holes. I marked the corners of the hole using the punch it'self as a template. Then drilled holes at the center of all the locations.

Using a hole punch I made nice round corners for the hole.

Using a nibbler tin snip to cut away the majority of the metal leaving a quarter inch or so to trim with offset tin snips. Supercoup NR1 Nibbler Shears

Using Plug weld pliers I welded up the holes along the edge of the hole I cut. Plugweld Pliers

And a little clean up with a ROLOC disc, my door looks a lot better and I have my hole to correct the window channel angle.

I picked up the hole punches I have at a garage sale years ago. It was at an estate sale of an elderly man who had fallen ill and his things were being sold off. Every time I use something I bought that day (a number of nice hand sheet metal tools) I think of that man and wonder about the projects he must have made. I am honored to be using his tools I'll tell you that.

Brian

So I thought that was the perfect place to place my holes. I marked the corners of the hole using the punch it'self as a template. Then drilled holes at the center of all the locations.

Using a hole punch I made nice round corners for the hole.

Using a nibbler tin snip to cut away the majority of the metal leaving a quarter inch or so to trim with offset tin snips. Supercoup NR1 Nibbler Shears

Using Plug weld pliers I welded up the holes along the edge of the hole I cut. Plugweld Pliers

And a little clean up with a ROLOC disc, my door looks a lot better and I have my hole to correct the window channel angle.

I picked up the hole punches I have at a garage sale years ago. It was at an estate sale of an elderly man who had fallen ill and his things were being sold off. Every time I use something I bought that day (a number of nice hand sheet metal tools) I think of that man and wonder about the projects he must have made. I am honored to be using his tools I'll tell you that.

Brian