Need valve spring recomendations. I come here because I know I wont get a wisecrack answer like FBook. 302 .030 over flatops and double humps with 2.02. We are running a reverse rotation hydraulic cam approx .480 lift, 260 duration @.050. We are stuck with this cam so I dont need cam recommendations just valve springs. Stock diameter with Comp rollers 1.5. Was turning 6500 in the motor it came out of with Vortec heads andVictor JR. You guys are the best!

Valve spring recommendations

Richiehd

Discussion starter

1,401 posts

·

Joined 2011

- Add to quote Only show this user

Need valve spring recomendations. I come here because I know I wont get a wisecrack answer like FBook. 302 .030 over flatops and double humps with 2.02. We are running a reverse rotation hydraulic cam approx .480 lift, 260 duration @.050. We are stuck with this cam so I dont need cam recommendations just valve springs. Stock diameter with Comp rollers 1.5. Was turning 6500 in the motor it came out of with Vortec heads andVictor JR. You guys are the best!

2,275 posts

·

Joined 2011

.480" is pretty low lift for a cam with 260 duration @ .050. Do you have the P/N? if so, which springs does CompCams recommend? My Comp catalog shows their #981 spring for a flat tappet hydraulic cam with up to .490" lift. But I suspect controlling the valves at 6500 would be your main concern. Comp also has a #26981 beehive spring. Its light weight should handle the revs better. The racers here should be able to give you more choices.

I also have to ask: Why reverse rotation? Is this marine engine? Also, why flat tops with a 3" stroke and 64cc chambers? No criticism here, just wondering.

I also have to ask: Why reverse rotation? Is this marine engine? Also, why flat tops with a 3" stroke and 64cc chambers? No criticism here, just wondering.

Richiehd

Discussion starter

1,401 posts

·

Joined 2011

Yes Marine engine. This is the setup we are stuck with, long story not worth the explanation, just trying to get this one back together. its 230 at .050 with .480 lift. Cam was in 350 but got some water in it. Had this long block available, was set up with solid flat tappet cam, Just dont want to wipe the cam out with too much spring pressure. I will compare springs tomorrow, and see where im at.

2,230 posts

·

Joined 2023

even in RH marine motors, the timing gears (not chain) spin the cam and the dizzy and the oil pump the way god intended. the firing order is just different ( and the crank knurling at the oil seals)

2,761 posts

·

Joined 2015

Ok then. How about this. I used AFR 8020 springs with Crower 00307 solid flat tappet, lightweight valves, and aluminum rocker arms up to 6700 rpm. The Crower cam is higher lift and more duration than your cam. If you can find equivalent springs that fit (diameter) your heads, then they should work fine for you to 6500 (unless your valve train is a lot heavier). These are the springs that AFR specs for their 195 Eliminator heads with hydraulic flat tappet but solid lifters are lighter weight and allow higher rpm.

AFR's 8020 spring is designed for use with hydraulic flat tappet cam shafts up to .550" lift.

1.437” OD Hydraulic Flat Tappet

125 lbs. on seat

325 lbs/in

.550” max lift

Max RPM 6100-6300

Steel Retainer: 8510

SBC/SBF Valve Lock: 9009

(1 Piece) or (Set of 16)

AFR's 8020 spring is designed for use with hydraulic flat tappet cam shafts up to .550" lift.

1.437” OD Hydraulic Flat Tappet

125 lbs. on seat

325 lbs/in

.550” max lift

Max RPM 6100-6300

Steel Retainer: 8510

SBC/SBF Valve Lock: 9009

(1 Piece) or (Set of 16)

23,072 posts

·

Joined 2007

For a stock diameter drop-on spring that would do the job, just about every cam company has something similar, this is a Howard's Cams spring, commonly used with solid lifter circle track budget and claimer engines.

Howards Cams Hydraulic/Mechanical Flat Tappet Valve Springs, 1.250" O.D., 115 @ 1.700", 300 @ 1.250" - Competition Products

Howards Cams Hydraulic/Mechanical Flat Tappet Valve Springs, 1.250" O.D., 115 @ 1.700", 300 @ 1.250" - Competition Products

2,232 posts

·

Joined 2002

325 lbs/in is right at the limit for using regular oil. Anything more and you'd need a racing oil or a high pressure additive. That's probably why AFR specs that for a flat tappet cam.

155 posts

·

Joined 2023

I would look at the beehive springs from PAC . They have quite a few offerings and the spring you need will be determined by your installed height. I have used the part number 1280x on GM crate engines and that is probably similar to what you need. The x suffix indicates that the material has been processed for sustained RPM usage like seen in oval track engines

Richiehd

Discussion starter

1,401 posts

·

Joined 2011

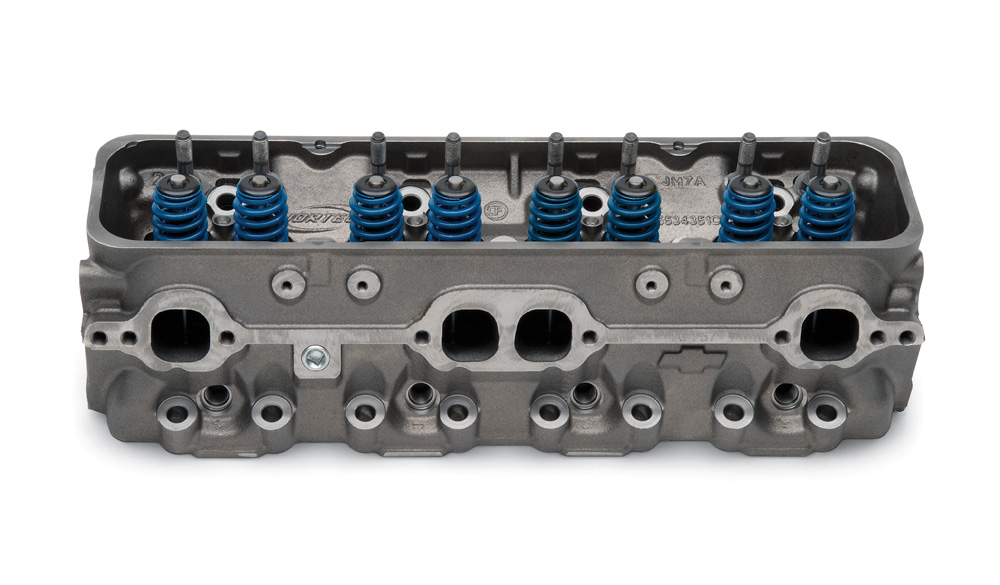

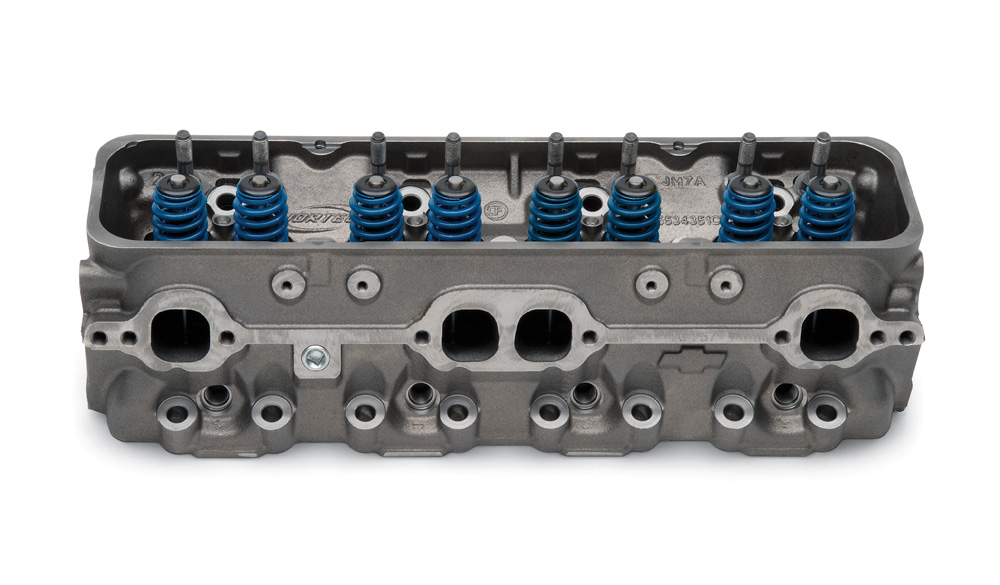

Should I start a new thread?Because we are going in different direction. Going with this Hydraulic flat tappet cam, Good lifters and cam. 490 lift. Reman 350 block and a set of slightly reworked Vortec heads. .100 longer valves and presently has larger springs and retainers. Trying to find springs that will work with 1.8 height and less than 300 pounds open. owner picked these heads up already done and with crew in studs. I just want to make sure I dont have too much spring pressure to tear this cam up

23,072 posts

·

Joined 2007

The springs would fit the need, but the kit is made for 8mm valve stems.

Stock hump heads are 11/32", so the valve locks and spring retainers won't be right

Stock hump heads are 11/32", so the valve locks and spring retainers won't be right

19,607 posts

·

Joined 2007

I hate to be the spoiler but really beehives are the way to go. The provide way better control with lots less pressure. The battle you’re getting into is too much and too little. Too much while usually giving good control greatly increases pressure at the cost of higher unit load at the lifter to lobe interface where too little pressure allows the lifter to possibly loft off the lobe over peak lift and bounce on the seat when reaching zero these being a bigger problem with modern grinds that crowd more duration and lift between the .050 points than old timey grinds with their ever so long ramps. Beehives also offer remedial relief for the Vortec head supporting .5 inch lifts without machining the top of the valve guide for retainer clearance.

It’s worth noting that pre 1974 GM factory cams were nitrated at the factory and oils of the period used a lot of ZDDP. After 1974 GM stopped nitrating cams and with or without a ton of ZDDP in the oil lobe and lifter wear became the problem it continues to be so ZDDP alone isn't the answer to this problem though helpful. Chevy on facrtory high performance engines with long, long cam duration and for the day also used a special hydraulic lifter with a hardened face these can still be found under part number 12371044, but unless you get a lucky hit finding these usually takes some shopping.

The Vortec production head is machined for the 1.241 diameter spring. Going larger starts to get iffy as this head is a thin wall casting that starts getting risky at at 1.38 and is totally out to lunch at 1.53. Cutting the spring perch larger weakens the outboard area from the guide to the spring padwhere the spring forces can if not will crack the casting, again a good reason as to why beehives are so attractive. GMPP sells thicker competition level iron Vortec’s but they ain’t cheap see link note the beehive springs.

Bogie

It’s worth noting that pre 1974 GM factory cams were nitrated at the factory and oils of the period used a lot of ZDDP. After 1974 GM stopped nitrating cams and with or without a ton of ZDDP in the oil lobe and lifter wear became the problem it continues to be so ZDDP alone isn't the answer to this problem though helpful. Chevy on facrtory high performance engines with long, long cam duration and for the day also used a special hydraulic lifter with a hardened face these can still be found under part number 12371044, but unless you get a lucky hit finding these usually takes some shopping.

The Vortec production head is machined for the 1.241 diameter spring. Going larger starts to get iffy as this head is a thin wall casting that starts getting risky at at 1.38 and is totally out to lunch at 1.53. Cutting the spring perch larger weakens the outboard area from the guide to the spring padwhere the spring forces can if not will crack the casting, again a good reason as to why beehives are so attractive. GMPP sells thicker competition level iron Vortec’s but they ain’t cheap see link note the beehive springs.

Small-Port Vortec Bowtie Cylinder Head Assembly

Check out the deal on Small-Port Vortec Bowtie Cylinder Head Assembly at GM Performance Motor

www.gmperformancemotor.com

Bogie

19,607 posts

·

Joined 2007

It is very common to run these metric Beehives from the Gen-3 to Gen-7 metric engines on standard measure Vortec and aftermarket heads. What is needed is either the Alex’s Parts or Comp Cams or from other sources which adapt the metric beehive to the Imperial valve stem locks.

alexsparts.com

alexsparts.com

Bogie

Beehive Valve Spring Retainers for 7 Degree 11/32" Applications, 16- 787

787 Beehive Retainer, Retainers, 11/32 Beehive Retainers, 787- 16, 16-787

alexsparts.com

alexsparts.com

Bogie

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 2.2M

- members

- 183K

- Since

- 2001

A forum community dedicated to hot rod owners and enthusiasts. Come join the discussion about restoration, builds, performance, modifications, classifieds, troubleshooting, maintenance, and more!

Explore Our Forums

Top Contributors this Month

View All

Scott Danforth

149 Replies

BogiesAnnex1

76 Replies

1971BB427

54 Replies