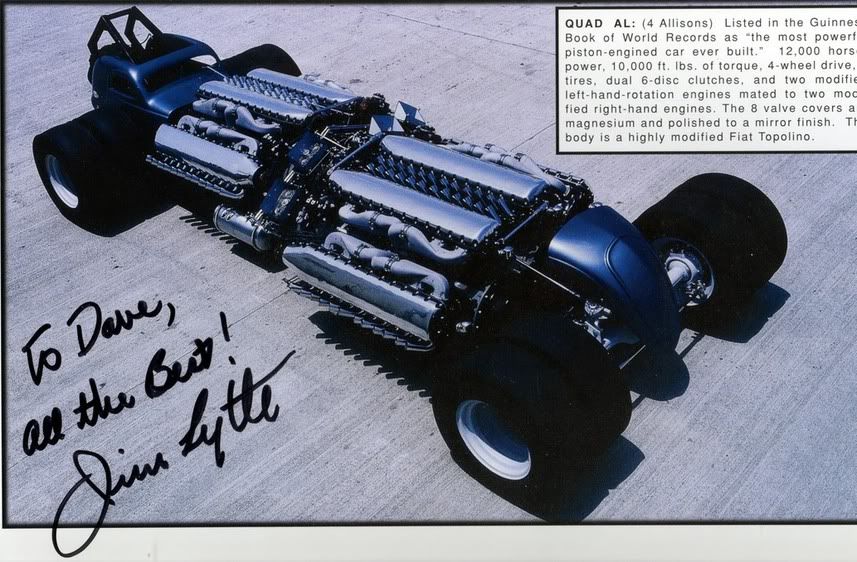

A V16, not V12, but interesting non the less:

Callaway Introduces 80-valve V16 Engine

Birmingham, U.K., January 13, 2005: Callaway Engineering and Cyclone Power Ltd. debut their cooperative project, the Callaway Cyclone 16-cylinder engine, at the Autosport Racecar Engineering Show (stand 10457 in the general motorsport section).

The unique engine is 4.0-liter normally aspirated V16 that features 5 valves per cylinder and makes over 550 bhp at 10,000 rpm and measures less than 36 inches long.

Says Reeves Callaway, Founder of Callaway Engineering, "A revolutionary Callaway project that is still under wraps requires a powerplant that packages 'in-line,' is visually interesting, and has an exciting and distinctive noise signature. A 'miniature' V16 at 10,000 rpm certainly has all of those features in spades."

Cyclone Power Ltd. Principal Mark Pemble says: "Our Cyclone V8s are potent and beautiful pieces of engineering. Putting two of them together is a logical configuration and a striking showcase for our company. Reeves Callaway's idea for this V16 is a complement to the partnership between Cyclone Power Ltd and Callaway Engineering, which has been formed to distribute the Cyclone V8 in North America. The V16 project will be the capstone for our normal business of selling V8 engines to the track-day racers."

Development:

The Callaway Cyclone V16 ran first in anger in November 2004. The development and testing has been carried out to a conservative and controlled step-by-step program that has, remarkably, been uninterrupted by even small failures. Since the V16 is comprised of two Cyclone V8s mechanically joined, and the individual V8s have hundreds of hours of run-time both on the dynamometer and in test vehicles, there was no reason to expect unreliability from this new configuration. We will complete testing after the Autosport debut at the Cyclone Power facility in Poole, Dorset, U.K.

Cost:

The Callaway Cyclone V16 is a development project at this stage. Prices may be had on application. It is unknown if there will be a commercial version. Clients for this and other engine configurations should contact Callaway/Cyclone.

Go to

www.callawaycars.com/V16 to download

" Photos

" Video files

" Sound files

Callaway Engineering provides contract engineering and manufacturing services for automotive OEM's, with focus on high-performance vehicles, systems and components. Facilities are located in Old Lyme, Connecticut; Irvine, California; and Leingarten, Germany.

Cyclone Power Ltd. is an engine development company that specializes in 'motorcycle derived' V8 engines. Their 2.0-liter Cyclone Power V8 is the basis of the Callaway V16 configuration.

For further information on the Cyclone V8, please go to

www.cyclonepowerltd.co.uk

Technical Specifications

Callaway Cyclone V16

4.0-liter 16 cylinder 90° V angle

5 valve / cylinder DOHC

bore 75.5 (3.0 in.) x stroke 55.75 mm (2.19 in) = 3994 cc (243.83 cu. in.)

aluminium block and heads, iron liners

12 (2 x 6) main bearings, plain

crankshafts: en40b steel, 2x, 4 journal, flat plane, nitrided

connecting rod, steel, plain bearing

compression ratio 11.5-1 naturally aspirated

power 550 bhp@10,000 rpm

torque 340 ft/lb@ 8,500 rpm

max rpm: 10,500

dry sump lubrication, 1 pressure, 3 scavenge stages

super unleaded fuel

EFI single fuel injector / single throttle / cylinder

Dimensions:

926 length (36.45")

540 width (21.25")

500 height (19.7") - to top of injector trumpets

dry weight: 152 kg (334 lbs.)

patented Cyclone cam drive system

clutch: superclutch triple plate 5.5"

water pump: ecu-driven, vari-speed electric unit

Beside the V16 are two V12's, a study in contrasts.