I recently purchased a magna flux dye penetration crack detection kit. Now im off to find more uses for it other than just checking heads for cracks. Are there any areas besides around bolt holes and coolant passages on engine blocks that should be checked for cracks? If you want to post a picture with a circled or highlighted area that would be very helpful. Thanks

zildjian4life218

Areas to crack check block deck surface

zildjian4life218

Discussion starter

1,841 posts

·

Joined 2008

- Add to quote Only show this user

I recently purchased a magna flux dye penetration crack detection kit. Now im off to find more uses for it other than just checking heads for cracks. Are there any areas besides around bolt holes and coolant passages on engine blocks that should be checked for cracks? If you want to post a picture with a circled or highlighted area that would be very helpful. Thanks

884 posts

·

Joined 2011

I assume you mean a V8?

The valley is an area where cracks occur. "Freeze" cracks are found on the outside of the block, usually near expansion plug holes. Main bulkheads where the oil hole goes "through" is another. Around the bottoms of the cylinders into the cam bore is another, usually from highly "abused" blocks.

When we "clean and mag" a block, we check the entire block.

Jim

The valley is an area where cracks occur. "Freeze" cracks are found on the outside of the block, usually near expansion plug holes. Main bulkheads where the oil hole goes "through" is another. Around the bottoms of the cylinders into the cam bore is another, usually from highly "abused" blocks.

When we "clean and mag" a block, we check the entire block.

Jim

20,998 posts

·

Joined 2009

Often by paying close attention to what the engine and components look like at disassembly will hint at possible cracks or blown head gaskets. If coolant is getting in the combustion chamber, it will look very clean compared to the adjacent cylinders from the steam cleaning effect. If the gaskets look good, cracks in castings would be the next suspect.

Cylinder heads can crack from the seat into the chamber, from bolt holes to coolant passages, guides can crack although this isn't too common at least in my experience. The chambers can crack between each other, especially the center cylinders where the crossover causes high or uneven heating.

Shown below are several images of magnetic test showing a cracks. These same cracks will also show up using dye penetrant inspection. Bolt holes to cylinders and/or coolant passages are good places to look on blocks. The starter bolt area of a Chevy block is another place that can be inspected for cracks. The starter nose is yet another.

Crack probably from freezing:

![Image]()

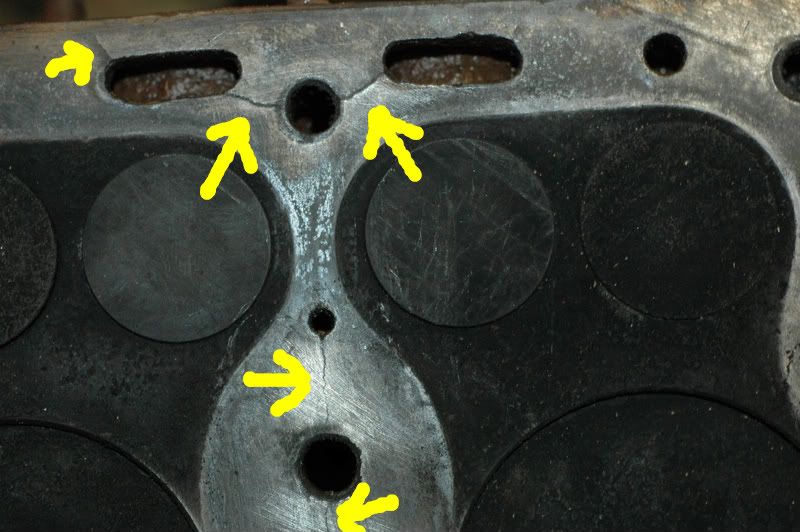

Below is a flat head block showing various cracks. A SBC can crack in similar places, especially from the steam holes of a 400 block:

![Image]()

Here's a diesel block, crack at red arrow, probably another at blue arrow. Webbing of a SBC can be cracked in similar places:

![Image]()

An article from Engine Builder mag: Looking For Leakers. There are others I'm sure.

Cylinder heads can crack from the seat into the chamber, from bolt holes to coolant passages, guides can crack although this isn't too common at least in my experience. The chambers can crack between each other, especially the center cylinders where the crossover causes high or uneven heating.

Shown below are several images of magnetic test showing a cracks. These same cracks will also show up using dye penetrant inspection. Bolt holes to cylinders and/or coolant passages are good places to look on blocks. The starter bolt area of a Chevy block is another place that can be inspected for cracks. The starter nose is yet another.

Crack probably from freezing:

Below is a flat head block showing various cracks. A SBC can crack in similar places, especially from the steam holes of a 400 block:

Here's a diesel block, crack at red arrow, probably another at blue arrow. Webbing of a SBC can be cracked in similar places:

An article from Engine Builder mag: Looking For Leakers. There are others I'm sure.

20,998 posts

·

Joined 2009

One other obvious area is the bore itself. You may find cracking parallel to the deck:

![Image]()

Also you might see it perpendicular to the deck:

![Image]()

When something gets dropped into the engine and it finds its way into the combustion chamber, there's a fair to good chance that the cylinder will crack. It can also happen from detonation or overheating, and from hydraulic locking the engine. That can bend a rod as well so a cracked cylinder would be something to look for if you see a bent rod, and vise versa.

Again, knowing the engine's history helps a lot and watching things carefully as the engine comes apart will often point you to a problem. Best is when you are able to hear or drive the vehicle to know if there seemed to be a problem in the first place. Things like oil in the coolant or coolant in the oil is a good indication of at least a bad head gasket but can also be a cracked casting.

I believe the main downside to dye inspection is it's more expensive to do, it requires some finesse, and can take longer to do. Depending on the type you are using, blocking out sunlight and/or using a special light source might be needed so that's an added hassle.

Also you might see it perpendicular to the deck:

When something gets dropped into the engine and it finds its way into the combustion chamber, there's a fair to good chance that the cylinder will crack. It can also happen from detonation or overheating, and from hydraulic locking the engine. That can bend a rod as well so a cracked cylinder would be something to look for if you see a bent rod, and vise versa.

Again, knowing the engine's history helps a lot and watching things carefully as the engine comes apart will often point you to a problem. Best is when you are able to hear or drive the vehicle to know if there seemed to be a problem in the first place. Things like oil in the coolant or coolant in the oil is a good indication of at least a bad head gasket but can also be a cracked casting.

I believe the main downside to dye inspection is it's more expensive to do, it requires some finesse, and can take longer to do. Depending on the type you are using, blocking out sunlight and/or using a special light source might be needed so that's an added hassle.

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 2.2M

- members

- 183K

- Since

- 2001

A forum community dedicated to hot rod owners and enthusiasts. Come join the discussion about restoration, builds, performance, modifications, classifieds, troubleshooting, maintenance, and more!

Explore Our Forums

Top Contributors this Month

View All

Scott Danforth

157 Replies

BogiesAnnex1

85 Replies

1971BB427

72 Replies