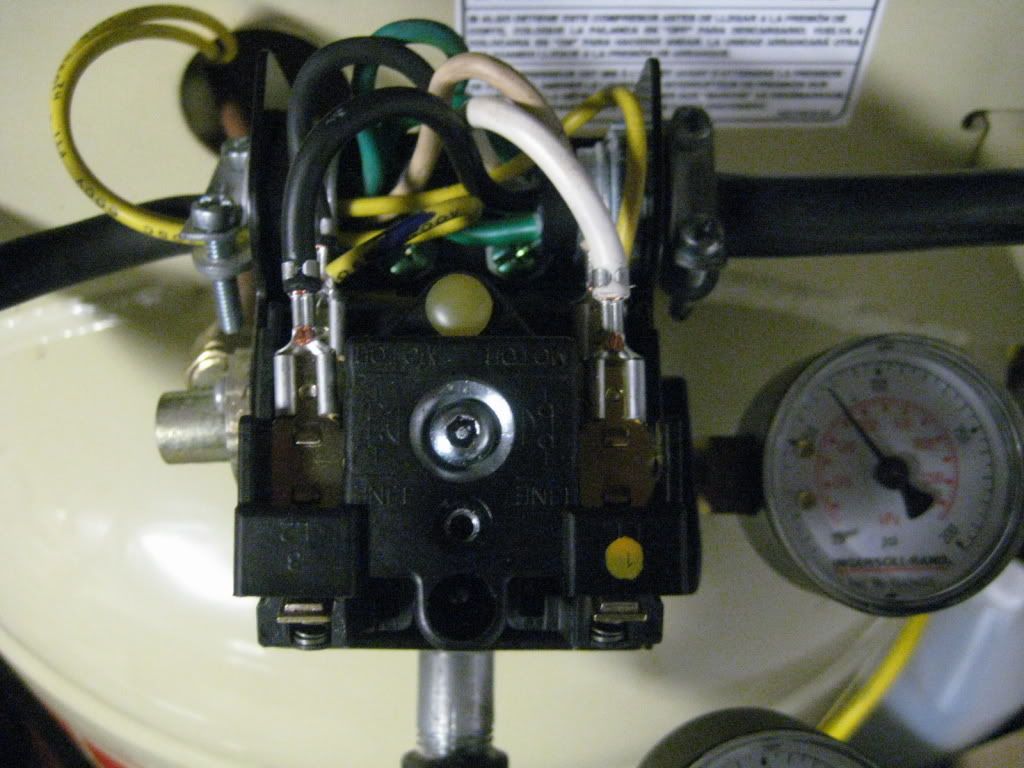

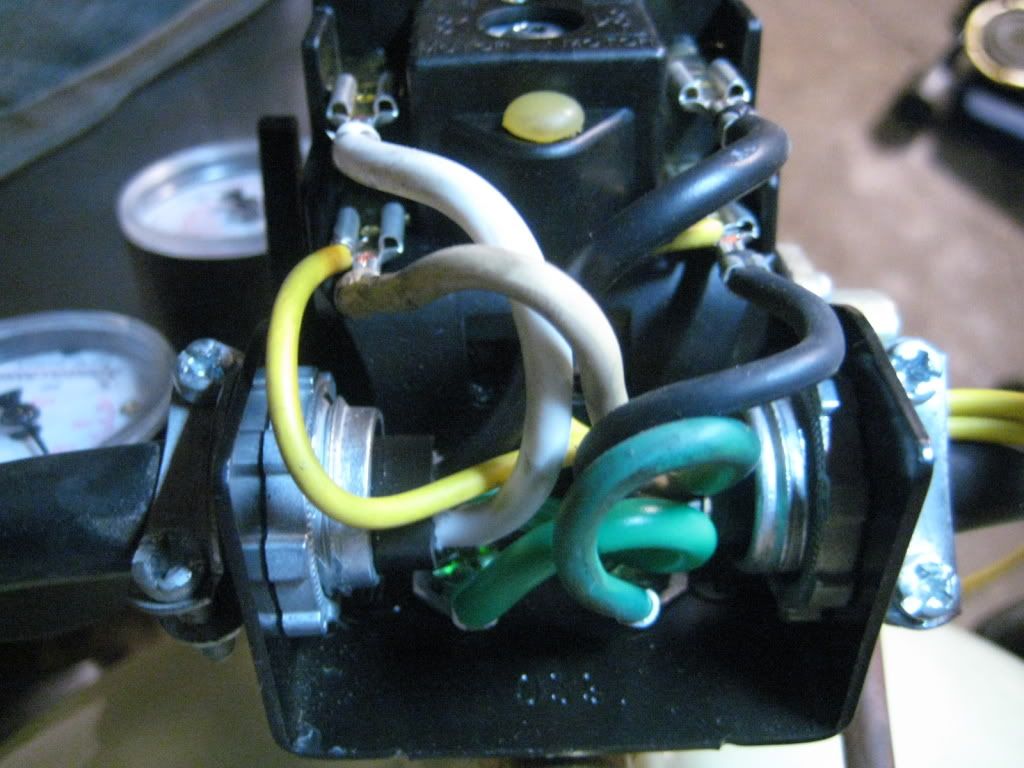

I have a little issue.. well actually a big issue. My compressor stops after it reaches a certain pressure (135psi i think?) without a problem, however when it dips below lets say 90psi it never kicks in, so basically I can run the tank dry and the darn thing will never start up again.

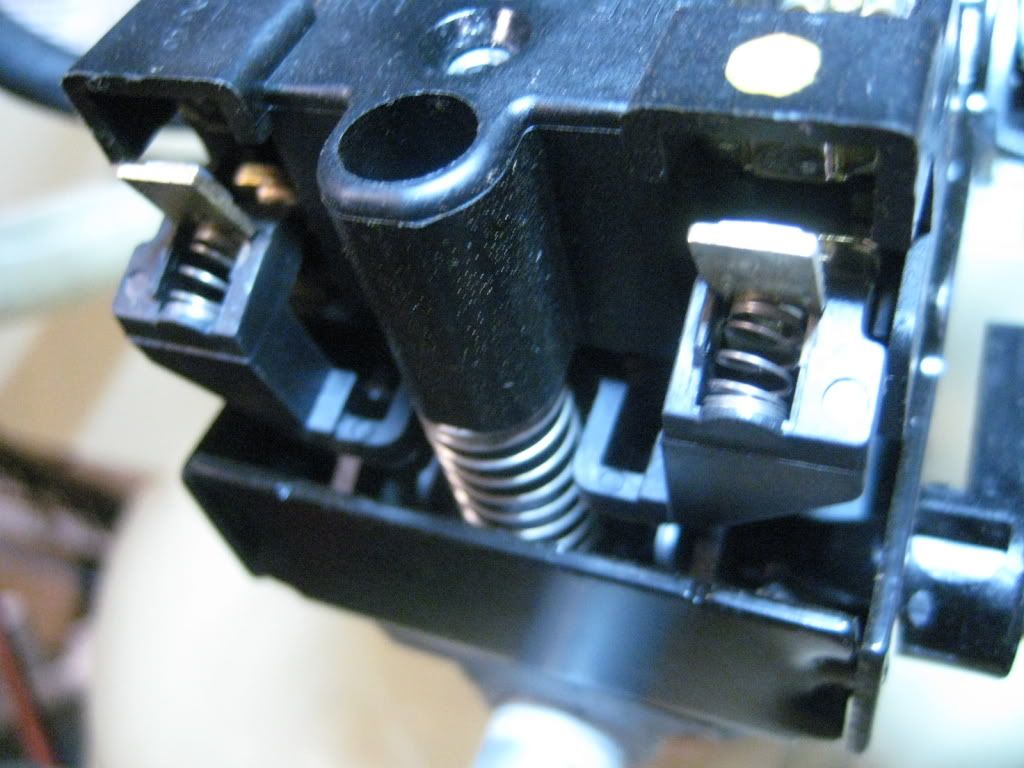

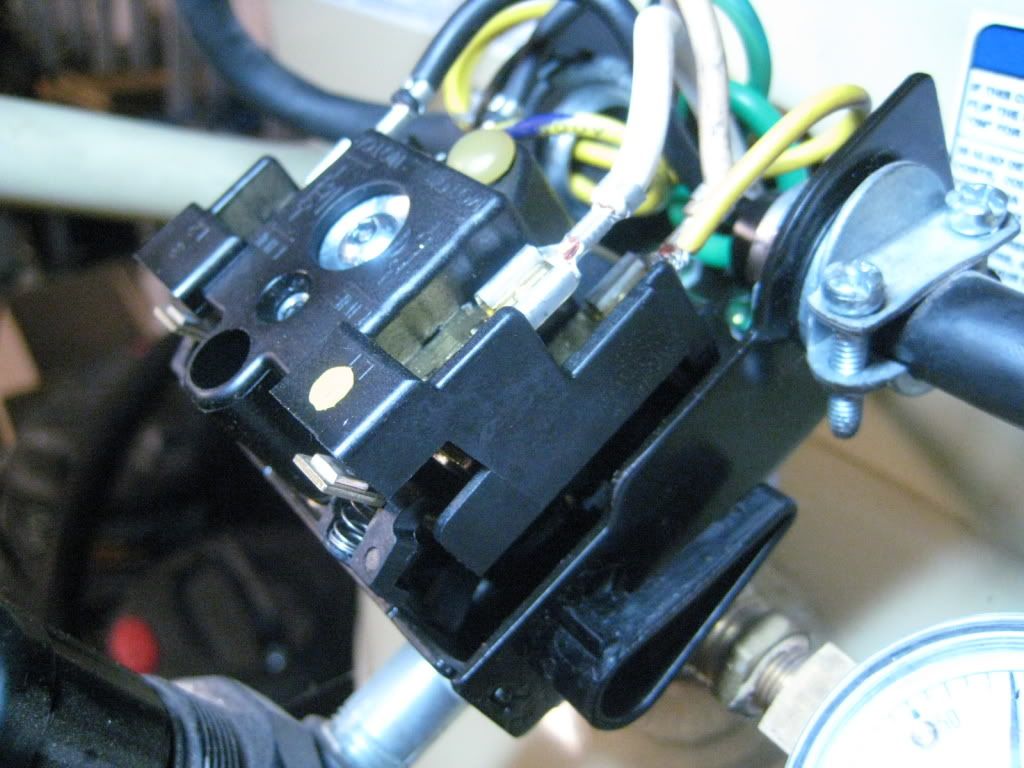

Also, I push down the lever to the Auto On position but nothing happens. I have to manually push these little contact tabs (which lock into place after) to get it to kick in, once the compressor reaches 135psi they spring out (disconnect).

I hope I make somewhat sense?

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

Also, I push down the lever to the Auto On position but nothing happens. I have to manually push these little contact tabs (which lock into place after) to get it to kick in, once the compressor reaches 135psi they spring out (disconnect).

I hope I make somewhat sense?