First, the cam in your engine is fine, perfectly normal and no worries there at all. Millions of SBC engines were built this way and millions have been modified for a LOT more power and they use the same type cam.

CAM BUTTON

Using a cam button on a flat tappet cam helps keep it from moving fore and aft, which causes the timing to vary a small amount and can also set up harmful harmonics in odd cases. But generally speaking, the way the lobes are ground w/a slight angle to them, along w/the way the distributor gear/cam gear interface, and the cam timing gear-to-block clearance and the timing set gear alignment all work together to keep the cam fairly well located in the block.

But if you have the time, desire, and patience to set it up w/a button and to be sure the timing set alignment isn't 'fighting' against the button, AND if the timing cover is sufficiently stiff to provide a solid point for the button to register off of, then go for it! Done correctly there's no real downside, even the cost is negligible.

BLOCKS:

Some '87-up SBC blocks were fully machined for the hydraulic roller cam. Some blocks had the bosses cast in place, but the bosses weren't drilled and tapped. And other blocks lacked the bosses altogether.

Some '87-up blocks are fully machined for a mechanical fuel pump while others have partial machining w/o a hole drilled through to the cam for the pump push rod. The link I gave you above goes into some detail on this.

FACTORY ROLLER:

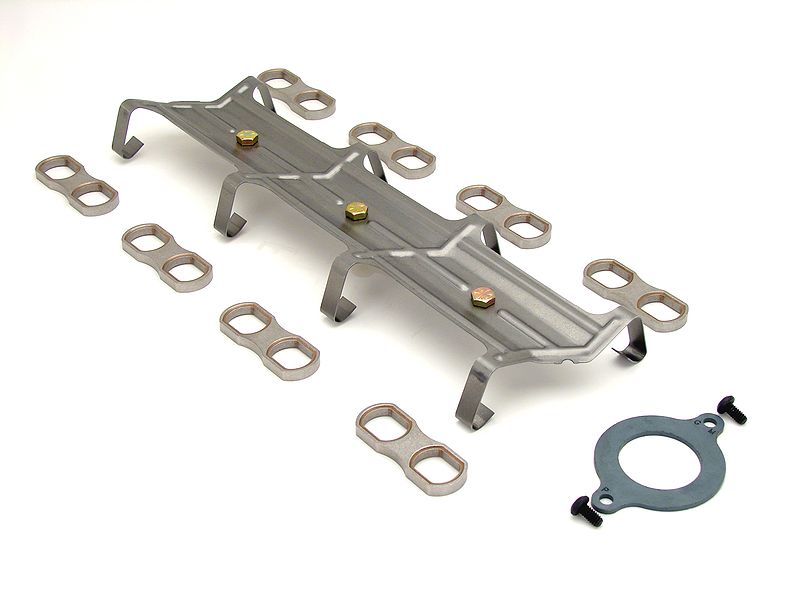

The dogbones hold the lifters in alignment and keep them from turning- which would instantly destroy the cam and lifter. The spider holds pressure on the dogbones to keep them in place. The retainer/thrust plate locates the roller cam in position; a roller cam lacks the angle on the lobes that work to keep a flat tappet cam from walking too much.

There are ways to use the factory roller cam spider and dogbones on a block w/o bosses. This requires drilling into the oil galley to mount the spider and the use of 3.4L V6 lifters (there are also other engines that use this same roller lifter). There are parts that are made to replace the dog bones that might give a better result. I have never used these retainers, so I can't comment further on them except to say the use of dog bones on an unmachined lifter boss doesn't seem like such a good idea to me, so the retainers might be a better solution. Now, there

are early non roller engines running around just fine that are set up w/the factory dog bones- so that's my opinion alone.

My thoughts are that unless the block was something special, I wouldn't go about it this way and would instead either find a roller block or use a retro roller cam and lifters.

Factory spider, dog bones, and cam retainer plate