I realized I'm going to be asking for some advice here on various topics and I'm hoping I can just put them all in one place.

For starters:

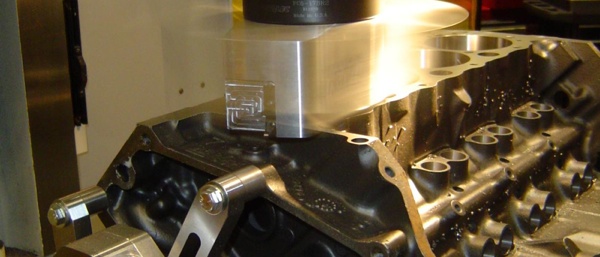

We are getting ready to install the crankshaft and piston assemblies. We did not balance the engine. We did not weigh the small ends and big ends separately, and we did not pay the machine shop to balance the crank. This is a 6,000 rpm max street motor. No sanctified racing is expected. Short blasts to 6000 rpm where we expect the camshaft to peak is it.

With that said:

We have weighed the piston and rod assemblies. we have a maximum spread of 9.1 grams. If i put the rods back in order, i have assembly pairs that are 7.8, 1.4, 2, and 0.2 grams from side to side.

playing with the assembly orders, i can get them down to 1.1, 0.2, 2.9, 2.6 grams side to side.

does it matter much given that we aren't really balancing the engine in any substantial way?

Just trying to make it as good as possible given what we are trying to do.

This is a 350 CI SBC with a targeted 400 hp if it matters any. The crankshaft is a remanufactured unit bought through the machine shop that did the block work.

For starters:

We are getting ready to install the crankshaft and piston assemblies. We did not balance the engine. We did not weigh the small ends and big ends separately, and we did not pay the machine shop to balance the crank. This is a 6,000 rpm max street motor. No sanctified racing is expected. Short blasts to 6000 rpm where we expect the camshaft to peak is it.

With that said:

We have weighed the piston and rod assemblies. we have a maximum spread of 9.1 grams. If i put the rods back in order, i have assembly pairs that are 7.8, 1.4, 2, and 0.2 grams from side to side.

playing with the assembly orders, i can get them down to 1.1, 0.2, 2.9, 2.6 grams side to side.

does it matter much given that we aren't really balancing the engine in any substantial way?

Just trying to make it as good as possible given what we are trying to do.

This is a 350 CI SBC with a targeted 400 hp if it matters any. The crankshaft is a remanufactured unit bought through the machine shop that did the block work.