Hello

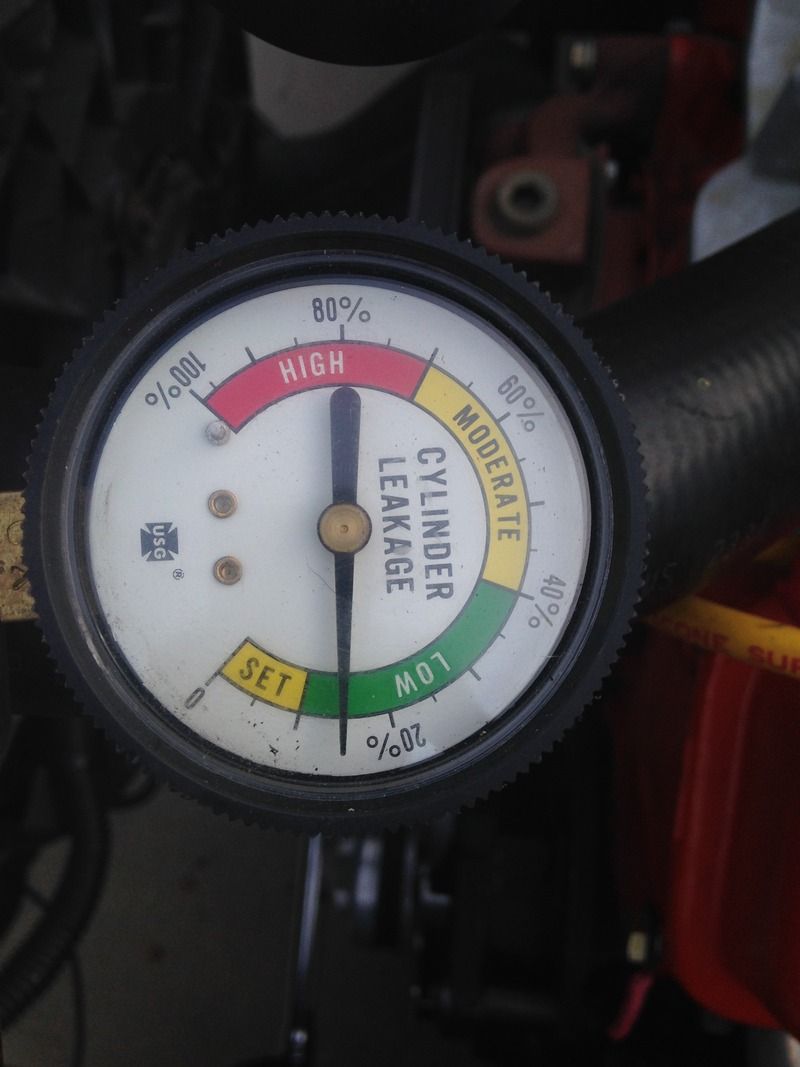

I was wondering if I could get some questions answered. I have a rebuilt sbc 350 that is burning oil. About a quart every hundred miles or so. I suspect the rings did not seat. I have access to a leak down tester and a compression tester. My question is will a compression test or leak down test prove the rings did not seat? I know that there are compression rings and there is a oil ring on the pistons. How will I know which ring or all rings failed to seat?

Or maybe someone can point me in the right direction as to how I can go about testing said engine and a possible fix before it goes off to new rings and a hone job?

Thanks in advance.

I was wondering if I could get some questions answered. I have a rebuilt sbc 350 that is burning oil. About a quart every hundred miles or so. I suspect the rings did not seat. I have access to a leak down tester and a compression tester. My question is will a compression test or leak down test prove the rings did not seat? I know that there are compression rings and there is a oil ring on the pistons. How will I know which ring or all rings failed to seat?

Or maybe someone can point me in the right direction as to how I can go about testing said engine and a possible fix before it goes off to new rings and a hone job?

Thanks in advance.